BONLAB BLOG

Thoughts

&

Scientific Fiction

Visualizing the drying and film formation of polymer latexes

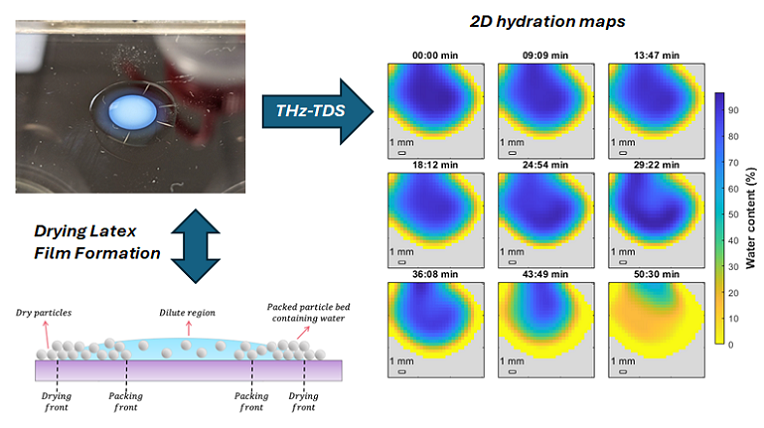

Polymer latex particles, typically 50-600 nm in diameter, are used in many applications, such as paper manufacturing, water-based adhesives, printing, and coatings. Commonly, a water-based formulation that contains these polymer colloids is used, often together with other components, such as pigments for opacity and color, fillers, and rheology modifiers. Each of the polymer latex particles consists of many individual polymer chains. These water-based dispersions are applied onto a substrate as a droplet or a film, after which these systems are dried. Visualizing this drying and film formation process in real time would greatly help in understanding how the properties of a dried film come about. In our paper, published in the American Chemical Society’s journal Langmuir, we used TeraHertz Time-Domain Spectroscopy (THz-TDS) to map the water content spatially in real-time during the drying process.

Polymer latex particles, typically 50-600 nm in diameter, are used in many applications, such as paper manufacturing, water-based adhesives, printing, and coatings. Commonly, a water-based formulation that contains these polymer colloids is used, often together with other components, such as pigments for opacity and color, fillers, and rheology modifiers. Each of the polymer latex particles consists of many individual polymer chains. These water-based dispersions are applied onto a substrate as a droplet or a film, after which these systems are dried. Upon evaporation of water, the individual components will pack closely. When little water remains in between, a so-called capillary under-pressure facilitates tight packing, and if the polymer latex particles are soft, it deforms them. The last stage of the film formation process is when polymer chains from one latex particle now diffuse into a neighboring latex particle and the other way around. This process ensures that the dried film has good adhesive and mechanical properties.

Visualizing this drying and film formation process in real time would greatly help in understanding how the properties of a dried film come about. In our paper, published in the American Chemical Society’s journal Langmuir, we used TeraHertz Time-Domain Spectroscopy (THz-TDS) to map the water content spatially in real-time during the drying process.

The use of TeraHertz Time-Domain Spectroscopy (THz-TDS) as a tool to visualize the water content in a drying polymer dispersion in real-time.

Emily Brodgen, a final year PhD researcher from BonLab, teamed up with Gonçalo Costa, a PhD researcher in the Department of Physics at the University of Warwick, working with the team of prof. Emma Pickwell-MacPherson, and together they studied the potentials THz-TDS could bring.

Prof. dr. ir. Stefan Bon says: “It is great to see this collaborative work. We believe that there are opportunities for THz-TDS to be used as an analytical tool in the field of water-based polymer dispersions, particularly how droplets or films dry after they have been deposited onto a surface. As you can read in the paper, which we very much see as a positioning study, there are great opportunities out there to refine the technique. We hope others are as enthusiastic as we are so that THz-TDS can be adopted wider as a measurement tool.”

The paper is freely available to all from ACS Langmuir and can be found here:

https://doi.org/10.1021/acs.langmuir.4c03103

For more information, please get in touch with prof. dr. ir. Stefan A. F. Bon directly.

Water-Based Acrylic Latexes are excellent Pressure Sensitive Adhesives when Branched

Water-based pressure sensitive adhesives (PSAs) are typically made by emulsion polymerization using a low glass transition temperature base monomer, such as n-butyl acrylate or 2-ethyl hexylacrylate, together with a range of functional comonomers. Typically these include a high glass transition temperature comonomer, such as styrene or methyl methacrylate and monomers that can promote wetting and undergo secondary interactions such as (meth)acrylic acid.

Water-based pressure sensitive adhesives (PSAs) are typically made by emulsion polymerization using a low glass transition temperature base monomer, such as n-butyl acrylate or 2-ethyl hexylacrylate, together with a range of functional comonomers. Typically these include a high glass transition temperature comonomer, such as styrene or methyl methacrylate and monomers that can promote wetting and undergo secondary interactions such as (meth)acrylic acid.

A golden rule for good adhesive performance is that the polymer latex particles must contain a certain fraction of gel, that is, cross-linked material. This typically is 50-70%. This gel content optimizes the balance between tack and cohesive forces within the adhesive.

Schematic of the branched polymer chain architecture approach to deliver good performance in pressure sensitive adhesives (PSAs).

In our paper, led by PhD researcher Emily Brogden and published in the RSC journal Polymer Chemistry, we challenged this view. Prof. dr. ir. Stefan Bon says: “We designed a range of polymer latexes with low gel content. To balance the adhesive forces, we introduced a branched polymer chain architecture instead. We show that excellent water-based acrylic PSAs can be made using this approach.”

Moreover, the chemical composition of our PSA was designed with sustainability in mind. The base monomer selected was the bio-based 2-octyl acrylate, the high Tg component bio-based 2-isobornyl acrylate. The other monomers and chain transfer agent show promise to be or become fully bio-based.

The paper entitled “Water-Based Polymer Colloids with a Branched Chain Architecture as Low-Gel Pressure-Sensitive Adhesives” has gold open access and can be read here:

BonLab designs a stick-on-demand adhesive for linerless labels

Labels are big business. A typical label has multiple layers: a topcoat for protection, the face stock, which contains the message in the form of text and/or images, a pressure-sensitive adhesive, and a release liner, which often has a release coating. The release liner and coating are only there to protect the label from sticking to things you do not wish it would stick to. You remove the liner when you wish to apply the label onto your substrate of choice, for example, a bottle containing a drink.

Imagine a label without a release liner and coating, imagine a label that could be activated at the moment you want it to stick to a substrate, a stick-on-demand linerless label.

BonLab has designed and developed a concept and prototype for a sustainable solution: a mesh reinforced pressure-sensitive adhesive for linerless label design.

Labels are big business. A typical label has multiple layers: a topcoat for protection, the face stock, which contains the message in the form of text and/or images, a pressure-sensitive adhesive, and a release liner, which often has a release coating. The release liner and coating are only there to protect the label from sticking to things you do not wish it would stick to. You remove the liner when you wish to apply the label onto your substrate of choice, for example, a bottle containing a drink.

Imagine a label without a release liner and coating, imagine a label that could be activated at the moment you want it to stick to a substrate, a stick-on-demand linerless label.

BonLab has designed and developed a concept and prototype for a sustainable solution: a mesh reinforced pressure-sensitive adhesive for linerless label design. The idea was worked out by Emily Brogden and prof. dr. ir. Stefan Bon, in collaboration with UPM Raflatac Oy, a global supplier of label materials for branding and promotion, information and functional labelling (patent application: WO2023105120A1). The complete study, which was done at the University of Warwick, is now published in the new journal RSC Applied Polymers.

A water-based pressure sensitive adhesive (PSA) is contained in a hard 3D mesh structure. This replaces the standard PSA layer of a label. It provides structural support upon storage and prevents the adhesive layer from sticking. In adhesive jargon: it shows excellent blocking resistance.

Upon short heat treatment, for example, upon contact with a hot sterilized glass bottle, the mesh will soften, allowing for adhesion to occur.

The 3D mesh structure was generated using a binary mixture of water-based polymer dispersions. One component is a standard PSA latex, and the other is a polystyrene polymer colloid. Film formation of the blend followed by a short annealing time led to the desired phase-separated mesh structure, as displayed in the figure below.

Visualization of the mesh structure in an acetone etched PVAc-PS model film (Film 1) a-c. a) SEM image of the top surface, b) a tilt adjusted image of the cross section after cutting away a section using FIB SEM with a film height of approximately 20 𝜇𝑚, and c) micro-CT 3D reconstruction of the etched film. Visualization of a similar mesh structure in a PSA-PS film (Film 2) d-f. d) SEM image of the top surface of Film 2, annealed for 60 𝑚𝑖𝑛 e) SEM image of the top surface (prepared similiarly to Film 2 but with only a 19 𝑚𝑖𝑛 annealing time) with a clean crack after freezing in liquid nitrogen and f) a cross section of Film 2, where the PS is tagged with hostasol methacrylate (green), taken using confocal microscopy (the original top surface of the cast film is at the top of the image).

Prof. dr. ir. Stefan Bon says: “I am immensely proud of the hard work done by all people involved to get the idea from a sketch on a piece of paper to a working prototype. A big thank you to PhD researcher Emily Brodgen, the paper's first author, who has been the driving force behind turning a concept into reality and has worked tremendously hard on the project for the last couple of years. The work has received excellent feedback from the academic and industrial scientific communities, with Emily winning multiple prizes for best talk and scientific poster.”

The paper can be accessed from the RSC Applied Polymers website:

https://doi.org/10.1039/D3LP00224A

A promotional video will be made available soon.